Health Ranger science lab tour: See the liquid handling automation robot from CWC Labs

03/07/2017 / By Mike Adams

I’ve been working hard in the lab these last few weeks, scripting liquid handling automation solutions for our new liquid handling robot. This is all part of my groundbreaking work on cannabinoid analysis and quantitation using extremely accurate mass spec instrumentation to quantify the concentration of CBD molecules found in the sample being tested. (This includes CBD, CBD-A, THC, CBG, and so on.)

Most labs currently use UV detection which is orders of magnitude less sensitive than mass spec detection. But in order to achieve the kind of laboratory consistency that matches the detection sensitivity of our instruments, we have to use automated liquid handling systems (i.e. a “robot”) for sample prep and standards prep.

As you’ll see in the video below, this robot is used for automating many different processes in the lab, including preparation of external standards, sample dilutions and preparation, carrying out serial dilutions and much more.

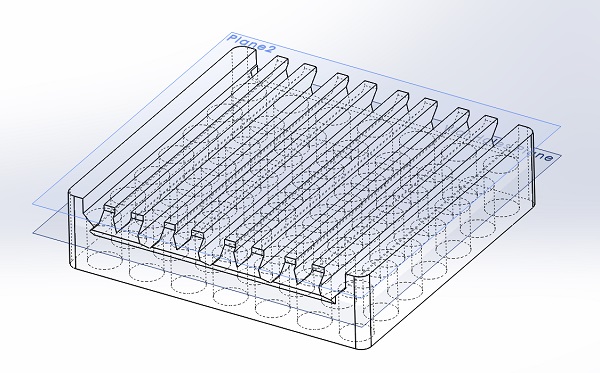

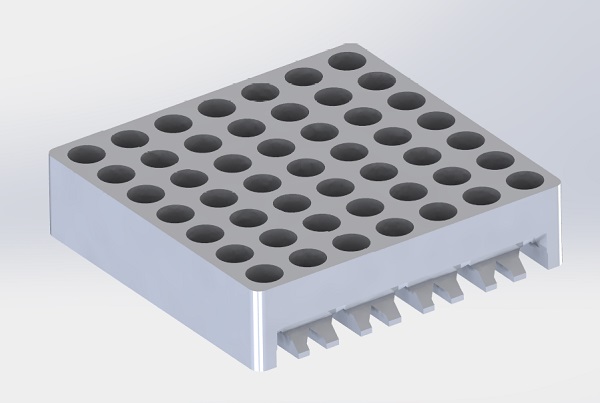

To make this system work, I had to use CAD software to design the 2mL vial trays you see in the video. After designing the trays, I printed them on a Lulzbot Mini 3D printer, which is the same printer I also use to print parts for the Food Rising Mini-Farm Grow System we released over a year ago. (A non-electric, self-watering, non-circulating hydroponic food grow system.)

Check out the video here to see the liquid handling automation robot in action, working with methanol:

Tagged Under: automation, CBD, Health Ranger, liquid handling, mass spec, quantitation, robot, sample prep, science lab